FAQ

How many rows do I need?

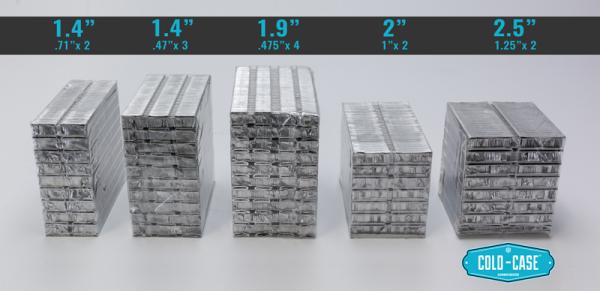

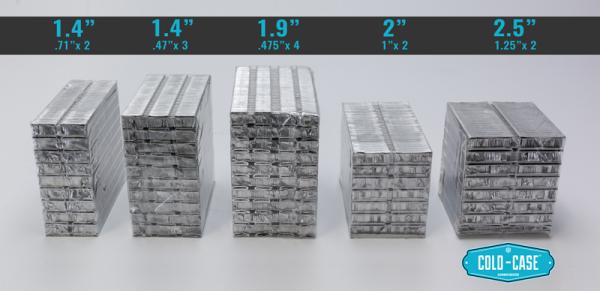

In aluminum, 2 rows of 1" or 1.25" tubes should be plenty for most street and mixed-use drag vehicles. Our 2 row models will outperform a copper/brass 4 row by about 10-15%! Also, you don't want a 3 or 4 row alumnum radiator. You want bigger tubes with an aluminum core because of the way it transfers the heat.

Which antifreeze should I use?

A 50/50 mix using distilled water and ‘green’ antifreeze is recommended. Aluminum does not seem to hold up well with 'orange' antifreeze products.

Will I lower my temperature if I increase the flow with a High flow water pump?

Not necessarily. Flow is not as important as pressure. You want pressure in your system to reduce cavitation(steam pockets that get trapped on the walls of the system. One commonly overlooked aspect of increasing pressure is the Water pump pulley to Crank pulley ratio. You always want your crank pulley to be bigger than your water pump pulley. (overdrive your water pump)

Can todays fuel affect the temperature of my engine?

Absolutely. Today's fuels burn a lot hotter than the past high octane fuels containing lead.

Should I go with Pusher or Puller fans?

Most vehicles are set up with puller Fans from the factory. Pulling fans pull air through the radiator at least 20% more efficient than pushers. One reason is that you can only create a suction affect by pulling air. A pusher fan would perform worse if a shroud was mounted on the pushing side. That would block forced air from hitting the radiator when at cruising speeds. Pusher fans also restrict air flow into the radiator at cruising speeds.

Are electric fans better than mechanical?

It does depend on the application. Sometimes electric fans actually rob HP from the car. If your mechanical fans are cooling better than you electric fan setup, there are a few things to check on. 1- Are the electric fans operating at the optimal speed? Do they have enough amperage draw/power? 2- Did you recalibrate or change your pulley system with the electric fans? To calculate the speed of the water pump at any given engine speed, simply divide the crank pulley diameter by the water pump pulley diameter. Then, multiply by the engine RPM. Example: A 4'' crank pulley ÷ 5'' water pump pulley = .8 × 1000 crank RPMS = 800 water pump RPMs or a reduction of 20%.

Do you use Epoxy?

Cold Case does NOT use any epoxy throughout it's manufacturing process. Literally all plastic tank radiators use epoxy to connect the tank to the aluminum core. Many aluminum radiator companies used epoxy to connect their aluminum tanks to the aluminum core as well. Even some of the best radiator companies used this method until fairly recently. The problem with epoxy is that it dries and eventually cracks from constant expansion and contraction of the heat of the radiator. Once a crack is formed, the radiator begins to 'weep'. This weeping reduces the pressure of a radiator and therefore lowers the boiling point. Basically, it reduces the efficiency of the radiator. Not to mention eventually the crack(s) are going to grow resulting in a complete failure. Therefore, the preferred method of connecting the tanks to the core is by an aluminum braising operation for longer radiator life.

Do your fan shrouds have louvers?

Debate continues as to whether to include louvers in the shroud. The louvers allow for better air flow at highway speeds as well as offering an ornamental look. With no louvers, the shroud creates a vacuum affect and increases air flow, speed and cooling efficiency at slow speeds. Several companies have even tried to settle the debate by adding rubber flappers to the shroud so as to keep the suction affect at idle speeds but allowing the forced air to blow the rubber flaps open at highway speeds. This is a clever idea but we feel these rubber flaps look cheap and are prone to falling off and still don't create a good enough seal. Cold Case maintains that most owners are looking to solve their overheating issues when stuck in traffic. Therefore, we maintain that the shroud should be fully sealed for maximum suction affect as this is dramatically more efficient at traffic idle speeds. The single 16" fan hole (or 2 12" fan holes) provide plenty of highway breathing for most situations

My radiator is pitting where the hoses go on. What causes that?

The most common cause is grounding issues causing electrolysis. Electrolysis occurs when electricity flows through your cooling system, leading to an electrochemical charge across the aluminum components. This results in rapid corrosion and severe damage, including discoloration, pitting, flaking, and pinholes in your cooling system. Electrolysis is most common in late model vehicles, hot rods, and street rods, typically caused by a defective or missing ground on one of the electrical sources. HOW CAN I TEST FOR ELECTROLYSIS? Testing for electrolysis involves measuring the voltage in your cooling system. Here's how you can do it: 1. Connect the negative lead of a volt/ohm meter to the battery ground. 2. Carefully insert the positive lead of the volt/ohm meter into the coolant inside the radiator, avoiding contact with the filler neck. 3. If the result is more than 0.10 V, it indicates electrical current flow in the system. 4. Test the voltage between the coolant and: a) the engine b) the frame by touching the negative lead to each respectively. 5. Repeat the test with the positive lead touching the radiator instead of the coolant. 6. To determine the faulty electrical source, conduct the test with the engine running and all vehicle accessories on. Have a friend or coworker systematically switch on and off components of the car while you monitor the meter. If voltage drops when disconnecting an electrical circuit, that circuit represents a likely electrical source. WAYS TO PREVENT ELECTROLYSIS: Preventing electrolysis requires careful monitoring and proper maintenance of your cooling and electrical system. Follow these tips to prevent electrolysis damage: 1. Ensure the radiator is not used as a ground, and that all components are functioning properly. 2. Periodically test your system and check for any discoloration or pinholes, especially around the tube-to-header joints and tubes near the center of the core by the electric fan mounts. By being proactive and taking these preventive measures, you can protect your cooling system from the harmful effects of electrolysis.

Why is there a cut in my radiator?

If you've received a radiator with a relief cut it is NOT a defect. They are stress relief cuts that allow optimal thermal expansion while maintaining the highest heat-transfer performance.